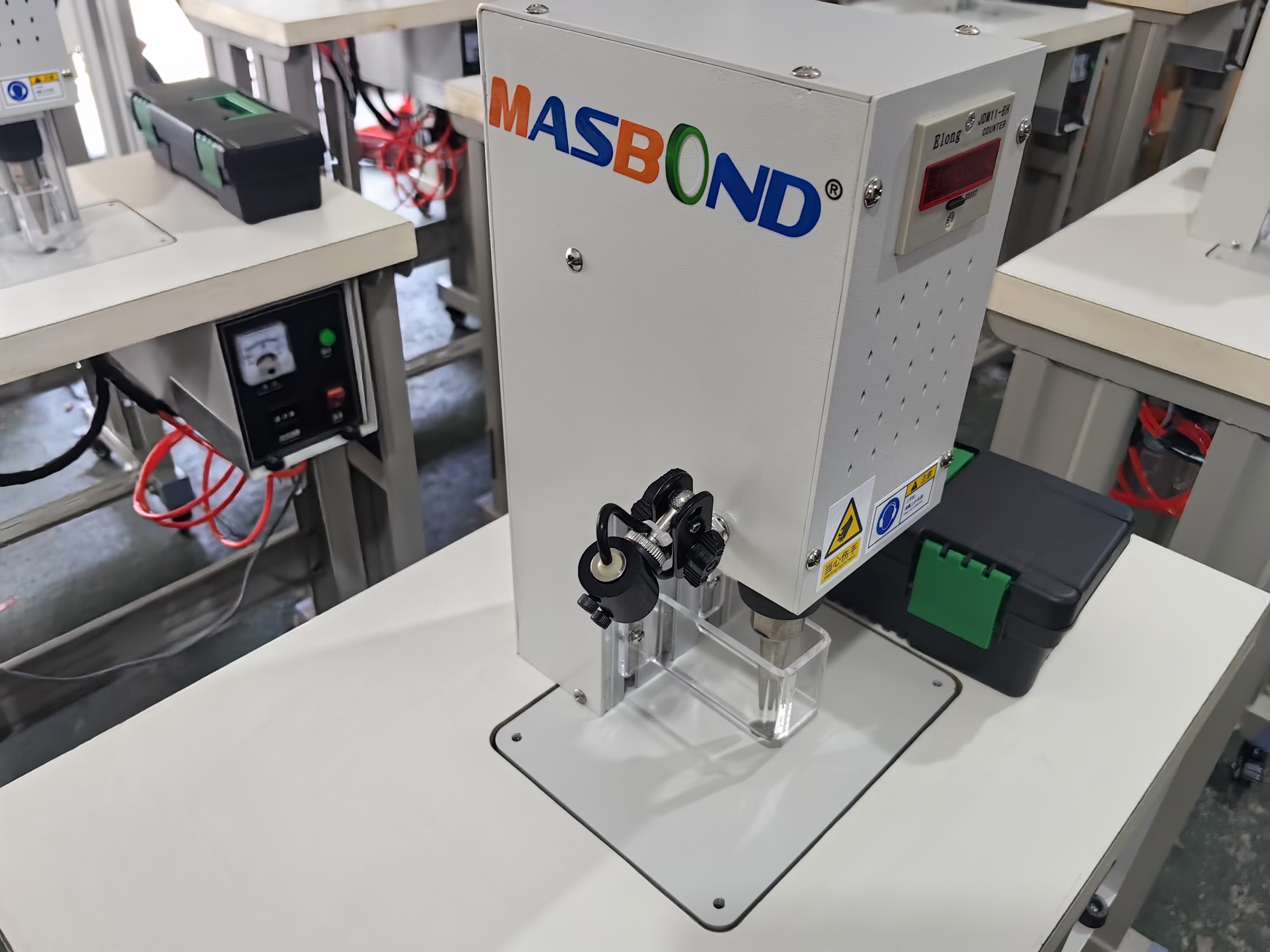

Ultrasonic welding machine

MASBOND Ultrasonic Welding Machine MS-24591

Supports complex processes such as curves, hollowing, multi-layer composites, and unlocks the possibility of clothing innovation

MASBOND Ultrasonic Welding Machine MS-24591

Look at the complete video how it's working

Application Scenarios & Product Advantages — Redefining the Boundaries of Seamless Manufacturing

Ultrasonic welding machine is an advanced technology joins synthetic materials to create perfect seams.

Apply on fabrics with 100% thermoplastic synthetic fibers or organic natural fiber.

The high-frequency mechanical vibrations(20-40KHz) passing through thermoplastic parts generating heat, to obtain an optimal temperature for bonding two fabrics

Sports Tech Apparel

Zero-pressure yoga waistbands: Bone-free reinforced bonding for high tensile strength and unrestricted movement

▸ 3D compression zones: Precisely engineered seams to enhance muscle support and energy efficiency

Functional Fashion Lingerie

▸Invisible side wings: Molecular-level fusion eliminates pressure marks and conforms to ergonomic curves

▸Antibacterial seamless gussets: Medical-grade sealing to prevent bacterial growth

Outdoor Waterproof Gear

▸Laser-sealed jackets: Zero leakage in -30°C cold and heavy rain conditions

▸Fully sealed wetsuits: Withstand 12-bar deep-sea pressure, extending seam lifespan by 20%

Premium Shapewear

▸ 3D contoured seams: 0.1mm precision to match body curves, redefining seamless aesthetics ▸ ▸Breathable mesh edge sealing: Simultaneous cutting and sealing to prevent fraying and unraveling

Five reason Core Technological Advantages

1.High-Speed Production

▸0.5–3 seconds per weld, enabling daily output of up to 100,000 units, ideal for agile supply chains

2.Eco-Friendly Innovation

▸No glue, no threads, no wastewater; certified by Blue sign® & GRS, reducing carbon emissions by 45%

3.Design Freedom

▸Supports ultra-fine 0.2mm curves and multi-layer complex shapes with <0.05mm deviation

4.Cost-Effective Solution

▸Saves 82% on sewing materials and reduces 70% of manual inspection, cutting total cost by 35%

5.Cross-Industry Versatility

▸Single machine compatible with apparel, footwear, medical, and automotive interiors, tripling equipment utilization

▸This seamless manufacturing technology offers significant advantages in production efficiency, environmental sustainability, durability, design flexibility, cost reduction, and cross-industry applicability.

The professional seamless bonding machine supplier and other automation solution provider - MASBOND

MASBOND founded in 2019, is focused on providing the latest seamless bonding solutions and other automation solutions to our clients. We are specialized in supplying kinds of seamless tape bonding machines, silicone glue bonding machines,automatic laser pocket welting machines etc.

MASBOND boasts a team of excellent experts dedicating to designing seamless processes and devoted to providing MASBOND solutions of seamless and automation to our customers with first-class products, outstanding credibility and meritorious service.

Need Seamless Bonding Machines or other automatic machines for your Shop or Factory?

Welcome to contact MASBOND, and we will reply within 24 hours.

Get A Quote

Feel free to have a quote on our tapes, we will reply within 48 hours.