Single Head Laser Cutting Machine

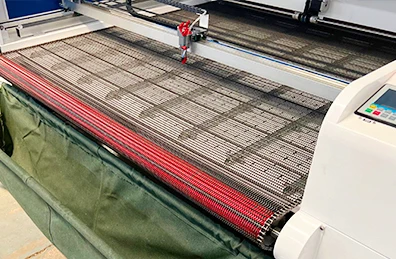

MASBOND Single Head Laser Cutting Machine With Auto feeding MS-241610

Suitable for The leather, cloth anticipates, rubber, fabric, textile, PU, plastics, paper, bag clothing, shoe etc. most of nonmetal materials.

MASBOND Single Head Laser Cutting Machine With Auto feeding MS-241610

Overview of MASBOND Single Head Laser Cutting Machine With Auto feeding MS-241610:

The laser cutting machine is a specialized device used for precision cutting of various types of fabrics. It utilizes the high energy density of a laser beam to generate heat effects on the fabric, enabling high-speed and accurate cutting. This method is suitable for industries such as textiles, clothing, and home decor. Laser cutting does not require contact, thereby avoiding material damage, while also possessing characteristics of high efficiency and quality processing.

Key features include:High precision cutting: Laser cutting machines achieve precise cutting edges, ensuring smooth edges without fraying or tearing, thus enhancing fabric quality.

Non-contact processing: Laser cutting is a non-contact processing technique, preventing physical damage to the fabric that may occur with traditional cutting methods like pulling or distortion.

High efficiency production: Laser cutting machines operate at high speeds, efficiently completing large volumes of fabric cutting tasks, thereby increasing production efficiency.

Flexibility and customization: Laser cutting machines can be adjusted flexibly according to design requirements, suitable for cutting various types of fabric, and capable of customizing complex shapes and patterns.

Minimal waste: Laser cutting technology minimizes waste during the fabric cutting process, maximizing material utilization.

Wide applicability: Laser cutting machines are suitable for various fabric types, including cotton, polyester, silk, and wool fabrics, making them widely used in industries such as clothing manufacturing, home decor, and automotive interior production.

Feature Of MASBOND Single Head Laser Cutting Machine With Auto feeding MS-241610:

Auto feeding table, more convenient and efficient for soft materials processing.

Suitable for mass production of large and medium-sized enterprises, as well satisfy the production needs of small enterprises and individual processors.

Machine working speed and laser power output can be adjusted in real time, greatly facilitating user's operation.

Laser power automatic compensation function, greatly improves the cutting effect.

High-performance laser engraving and cutting control system.

Applicable to various fabrics, smooth cutting edge without fins or burrs.

Technical Parameters of MASBOND Single Head Laser Cutting Machine With Auto feeding MS-241610:

| Model | 1610With autofeeder | Graphic format supported | *.plt, *.dst, *.dxf, *.bmp, *.dwg, *.ai, *.las, supporting AutoCAD and CorelDraw |

| Laser type | CO2 glass laser tube, wavelength 10.6μm, water-cooled | Software supported | CorelDraw, AutoCAD |

| Laser power | 100w, 130w, 150w | Control system | RuiDa DSP Off-line control system, laser power 0~100% adjustable |

| Working area | 1600x1000mm | Minimum letter size | Chinese 2.0x2.0mm, English 1.0x1.0mm |

| Engraving speed | 0-1000mm/sec | Working voltage | Single phase 220V/50Hz (Optional: 220V/60Hz, 110V/60Hz) |

| Cutting speed | 0-500mm/sec | Working condition | Temperature 0~45 Celsius; Humidity 5%~95% no condensation |

| Repeating location | ±0.01 | Driving system | Stepper motor |

| Transmission type | Belt transmission | Machine table | Blade table (alternative: honeycomb table) |

Get A Quote

Feel free to have a quote on our tapes, we will reply within 48 hours.