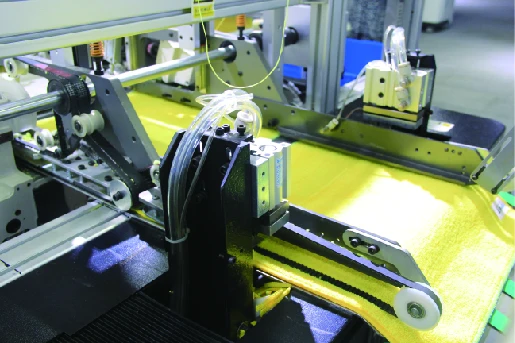

Microfiber Car Towel Sewing Machine

MASBOND Full Automatic Towel Making Machine with Wrap and Weft Knitting

Suitable for the production of single and double layer fabric edge stitching technology products on warp and weft knitted fabrics,such as towels, pillowcases, bath towels, hair dryers, mesh towels, dishwashing towels, spinning filter bags, etc.

MASBOND Full Automatic Towel Making Machine with Wrap and Weft Knitting

Feature of MASBOND Full Automatic Towel Making Machine With Wrap and Weft Knitting:

Overlock Two Edges Continuously, Cut Off Automatically.

Auto Label-sewing (Multiple Label Optional).

Auto Fabric Cutting and Thread Trimming..

Auto Stack-up.

Intelligent Touch Operating System.

Auto Button-Start,Convenient Operation.

Auto Edge-cutting,Size-Standardized.

1500pcs/h, with label attachment available, integration of cutting and sewing, ultrasonic thread cutting, automatic folding

What benefits does the manufacturing industry gain from using an ultrafine warp and weft knitting towel machine?

Increased Production Efficiency: The fully automatic towel machine and the ultra-fine warp-knitting towel machine enable highly automated production processes, significantly enhancing production efficiency. Compared to traditional manual or semi-automatic machine production, the fully automatic towel machine can weave and finish towels more quickly and accurately, saving a considerable amount of labor and time costs.

Reduced Production Costs: Automated production reduces labor costs and material waste, thereby lowering production costs. By optimizing production processes and improving production efficiency, the fully automatic towel machine and the ultra-fine warp-knitting towel machine significantly reduce the production cost per unit, enhancing the competitiveness and profitability of enterprises.

Improved Product Quality: The fully automatic towel machine and the ultra-fine warp-knitting towel machine enable precise control of weaving parameters, ensuring the stability and consistency of towel quality. Through automated control during the production process, product quality is subject to stricter monitoring, reducing quality issues caused by human factors and enhancing product quality and reliability.

Enhanced Production Flexibility: The fully automatic towel machine and the ultra-fine warp-knitting towel machine are versatile and flexible, allowing rapid adjustment of production lines according to market demand to produce towels of different specifications and styles. This flexibility helps enterprises better respond to market changes and customer demands, improving production adaptability and flexibility.

Energy Resource Conservation: Automated production processes typically allow for more efficient utilization of energy resources, reducing energy consumption and emissions, thereby reducing the environmental impact of production and aligning with sustainable development requirements.

Technical Parameters of MASBOND Full Automatic Towel Making Machine With Wrap and Weft Knitting:

| Parameter | Front Part | Rear Part | Automatic Collection Device |

| Weight | 360kg | 1000kg | 175kg |

| Dimension | 360*170*200cm | 180*250*200cm | 207*89*128cm |

| Power | 2.5kw | 6.5kw | 0.62kw |

| Voltage | 220v | 380V | 220V |

Air pressure | 0.6MPA | 0.6MPA | 0.6MPA |

Hourly Capacity | 750m/h | 1450pcs/h 40*40cm | 720pcs/h |

Size range | 230mm-750mm | 180mm- 800mm | length: 23-80cm width: 23-60cm |

Sewing SPD | 500-4500r/min | 500-4500r/min | / |

Get A Quote

Feel free to have a quote on our tapes, we will reply within 48 hours.