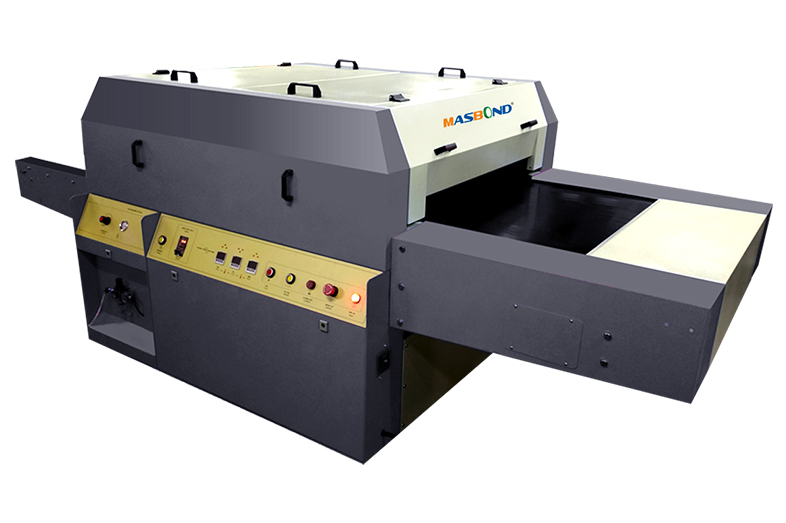

Grawler Type Continuous Heat Press Fusing Machine

MASBOND Grawler Type Continuous Heat Press Fusing Machine MS-600L/900L

Flat press for types of seamless clothing

MASBOND Grawler Type Continuous Heat Press Fusing Machine MS-600L/900L

Feature of MASBOND Grawler Type Continuous Heat Press Fusing Machine MS-600L/900L:

Equipped with the latest design of pneumatic pressure shaft system, the glue particles between the fabric and the lining are evenly distributed to promote further fusion of the glue particles to achieve better results. Thus, the pressure on the fabric will not be increased and the feel of the fabric will not be affected at all.

Independent control of the pressure axis allows for finer adjustment of the fabric and lining for adequate bonding.

Pneumatic deflection device and belt adopts cylinder tensioning device, thus making the belt more stable and durable.

Rotating plucking device is used for discharging to force the material off.

Equipped with discharge cooling device, which can make the bonding part cool down quickly and improve the working efficiency.

The belt is equipped with internal and external double cleaning device, which can automatically keep the inside and outside of the belt clean, thus enhancing the service life.

Super large silicone shaft with 145mm diameter, suitable for various materials.

MS-600L is equipped with 6 groups of heating zones in 2o independent temperature control groups. The heating area is up to 1.3 meters long, which makes the belt fit the fabric more closely and effectively so that the color of the material is uniform.

MS-900L is equipped with 9 groups of heating zones in 3 independent temperature control groups. The heating area is up to 1.3 meters long, which makes the belt fit the fabric more closely and effectively so that the color of the material is uniform.

Technical Parameters of Crawler Type Continuous Heat Press Fusing Machine :

| Voltage | 3P/380V | Power | 22Kw |

| Air Source | 0.4-0.6Mpa | Net Weight | N/A |

| Heating Size | Width 600mm(MS-600L) | Machine Size | 315*125*135cm |

| Max Temp | 195℃ | HS Code | 8451300000 |

Get A Quote

Feel free to have a quote on our tapes, we will reply within 48 hours.