Automatic Silicone Socks Screen Printing Machine

MASBOND Automatic Silicone Socks Screen Printing Machine MS-AMN-12

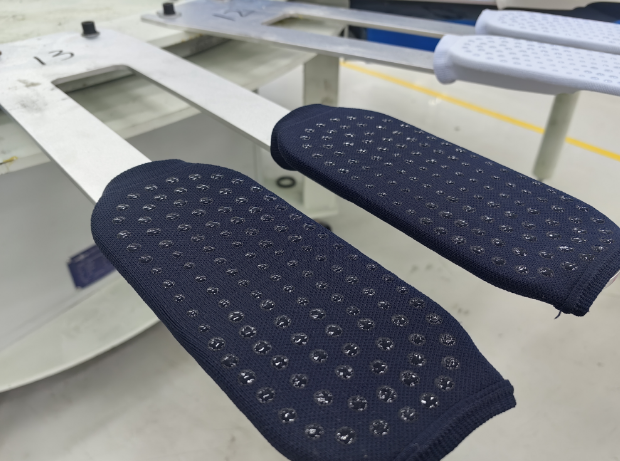

single-color silicone screen printing machine is a specialized piece of equipment used to transfer single-color silicone onto the surface of products such as textiles, footwear, socks, and more through the screen printing process.

MASBOND Automatic Silicone Socks Screen Printing Machine MS-AMN-12

A single-color silicone screen printing machine is a specialized piece of equipment used to transfer single-color silicone onto the surface of products such as textiles, footwear, socks, and more through the screen printing process. It is mainly applied to print simple, single-color patterns, commonly found in products requiring anti-slip, protective features, or decorative designs.

Features of a Single-Color Silicone Screen Printing Machine

Single-color printing: This type of machine is typically used to print silicone patterns in a single color, suitable for designs that are simple or only require one color.

Screen printing process: Silicone ink is evenly transferred through the mesh holes of the screen onto the substrate (such as fabric, paper, or plastic), creating clear-edged patterns.

Adaptability to various materials: In addition to textiles, the single-color silicone screen printing machine can be used for printing on other substrates such as leather and plastic, offering broad application possibilities.

Why Use a Single-Color Silicone Screen Printing Machine

Cost-effective: For products requiring simple designs, such as basic non-slip socks, gloves, or sports equipment, single-color printing machines are less expensive and meet production needs, avoiding the high investment of multi-color printing equipment.

Efficiency: Since only one color is involved, the printing process is relatively simple and fast, ideal for mass production of standardized products, significantly boosting production efficiency.

Suitable for basic products: Many basic functional products in the market, such as non-slip socks and protective gloves, only need a single color silicone layer. Using a single-color machine for these products can save time and costs effectively.

Reduced complexity: Operating a single-color silicone screen printing machine is simpler, with easier maintenance and adjustments. There is no need for frequent changes and alignment of multiple color plates, reducing production complexity and errors.

High stability: Compared to multi-color printing, single-color printing has lower requirements for color matching and printing precision, ensuring stable and consistent output, and reducing defect rates.

Environmentally friendly and material-saving: Single-color silicone printing reduces silicone and pigment waste, making it particularly suitable for companies focused on environmentally friendly production.

Application Scenarios

Single-color silicone screen printing machines are suitable for products that do not have high color requirements but emphasize functionality (such as anti-slip, protection) and durability. Common application scenarios include:

Non-slip socks, yoga socks

Industrial gloves, workwear

Surface protection for sports equipment

Technical Parameters of MASBOND Single color Sock screen printing machine with drier MS-AMN-12 :

| Power | 15KW | Air Source | 0.5-0.7Mpa |

| Voltage | 380v/50hz/3 phase | Net weight | 1710kg |

| Machine Size | 340-280*130cm | HS Code | 8443192290 |

| Mesh Dimension | 55*38cm | Capacity | 1000-1500 pairs/h |

Get A Quote

Feel free to have a quote on our tapes, we will reply within 48 hours.