Automatic Silicone Screen Printing and Extrusion and Reversing Machine

MASBOND Automatic Silicone Screen Priting&Extrusion&Reversing Machine MS-NY602

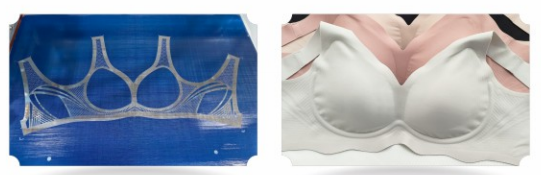

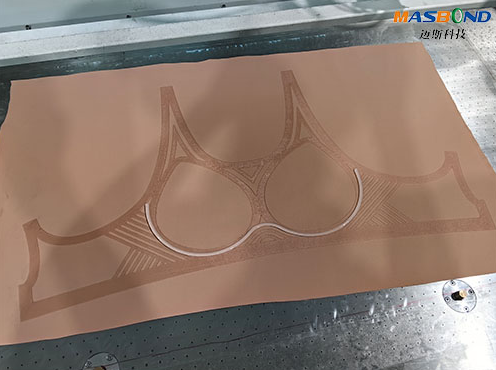

Applicable to various seamless bra、lingerie、yoga、barbie pants and t-shirt etc.

MASBOND Automatic Silicone Screen Priting&Extrusion&Reversing Machine MS-NY602

European Standard Module Configuration:

Automatic Glue Mixing and Dispensing: Provides a precise 1:1 mixture through dynamic mixing, ensuring consistent quality.

Adjustable Glue Volume and Timed Dispensing: Glue volume can be adjusted as needed, with timed dispensing options available.

High Precision and Bubble-Free Application: Ensures even thickness with high precision, eliminating bubbles.

AB Ratio Monitoring: Monitors the AB ratio to prevent uneven glue proportions.

Integrated Reflux Device: Suitable for use with a range of both thin and thick glues.

Dual Moving Beds for Alternating Operation: Two moving beds enable alternating operation, making production more automated.

Automatic Reversing Design: Simplifies the process, reduces labor costs, and enhances production efficiency.

Enhanced Silicone Extrusion: Combines with screen printing technology to improve the structural integrity of products like underwear.

Grating Protection Device: Includes a grating protection device for enhanced safety.

Technical Parameters of MASBOND Automatic Silicone Screen Priting&Extrusion&Reversing Machine MS-NY602:

| Voltage | 200V/50-60Hz | Power | 3Kw |

| Barrel | 5 Gallon | Machine Size | 3365*1255*1800mm |

| Air Pressure | 0.6-0.8Mpa | Working Stroke | 110*70cm |

| Weight | 800kg | HS Code | 8443192290 |

Get A Quote

Feel free to have a quote on our tapes, we will reply within 48 hours.