Ultrasonic Bonding &Bar-Tack Machine

MASBOND Ultrasonic Bonding & Bar-Tack Machine MS-UD20

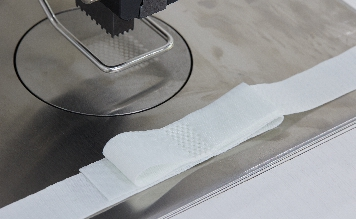

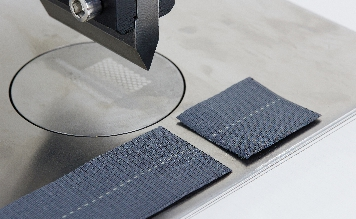

Cutting and bar-tack of varies of fabrics

MASBOND Ultrasonic Bonding & Bar-Tack Machine MS-UD20

Overview of Ultrasonic Bonding & Bar-Tack Machine MS-UD20:

Garment Ultrasonic Bonding & Bar-Tack Machine is a kind of machine used in garment production, which is mainly used for bonding, beating (edge treatment) and cutting fabrics. The following is a general overview of the machine:

Working Principle:

This machine utilizes ultrasonic technology to heat the edges of fabric and bond them together, forming smooth edges.

Ultrasonic vibrations generate heat through friction within the fabric, softening the surface fibers and bonding them together.

Main Functions:

Bonding: Bonds the edges of two or more pieces of fabric together, replacing traditional sewing methods. Edge

Folding: Processes fabric edges to make them smooth, neat, and prevent fraying. Cutting: Some models may also have cutting functionality to trim fabric as needed.

Operation:

Operation is typically straightforward, with parameters such as temperature and amplitude set through a control panel or digital interface.

Operators place fabric on the machine, adjust its position, and initiate processing.

Applications:

Primarily used in the apparel manufacturing industry, especially for edge treatments like collars, cuffs, and hems.

In addition to apparel, this technology can be applied to other textile products such as home furnishings and automotive upholstery.

Advantages:

Efficiency: Ultrasonic bonding and edge folding machines are generally faster than traditional sewing methods.

Aesthetics: Edges bonded and folded by this method are smooth, neat, and less prone to fraying.

High Automation: Some models offer automation features, enhancing production efficiency.

Precautions:

Operators should prioritize safety, avoiding contact with moving machine parts or hot surfaces.

Regular maintenance is essential to ensure proper operation and precise processing results.

Features of Ultrasonic Bonding & Bar-Tack Machine MS-UD20:

Fast ultrasonic spot welding according to the shape of the mould, forming in one step.

Laser positioning device with high efficiency.

Customizable various spot pattern moulds.

A movable upper die device greatly improves the service

life of upper and lower dies.

Freely adjust pressure.

Available for cutting and bar-tack.

Easy and convenient to change the mould.

Technical Parameters of Ultrasonic Bonding & Bar-Tack Machine MS-UD20:

Ultrasonic Frequency | 20HZ | Working Speed | N/A |

Power | 0.8Kw | Air Source | 0.5Mpa |

Voltage | 220V | Net Weight | 40kg |

HS Code | 8451300000 | Machine Dimension | 116*60*115CM |

Get A Quote

Feel free to have a quote on our tapes, we will reply within 48 hours.