What is the single color sock screen printing machine?

MASBOND Anti-Slip Sock Screen Printing Machine: Technology Principles, Applications, and Development

Introduction

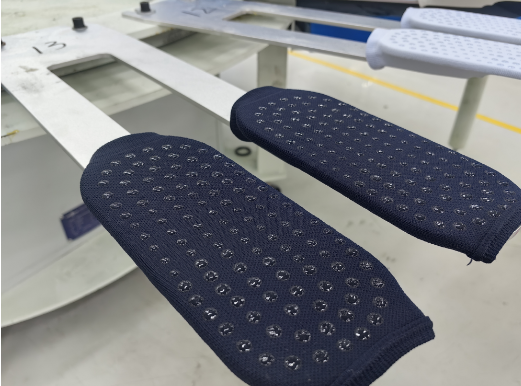

An anti-slip sock screen printing machine is specialized equipment designed to print anti-slip patterns or logos on the surface of socks. As people’s demands for a higher quality of life increase, anti-slip socks have gradually become a popular product in the market, particularly among children, the elderly, and athletes. Anti-slip socks effectively prevent slipping and falling, enhancing the safety and comfort of the wearer. The screen printing machine is the key equipment for realizing these anti-slip patterns, making its technical principles, operational processes, and market potential worthy of in-depth exploration.

Working Principles of the Anti-Slip Sock Screen Printing Machine

Overview of Screen Printing Technology

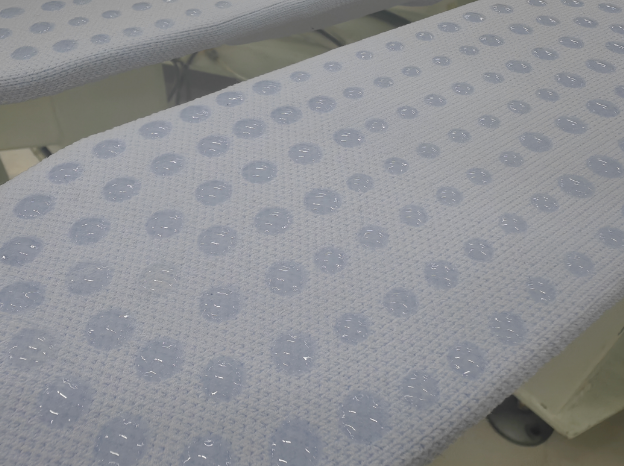

Screen printing is a technique that involves transferring ink through a pre-made screen (also known as a stencil) onto a substrate (such as fabric, paper, plastic, etc.). The main feature of screen printing is its controllable thickness, and its ability to print on various irregular surfaces, making it particularly suitable for producing anti-slip socks.

Structure of the Anti-Slip Sock Printing Machine

The core structure of an anti-slip sock screen printing machine includes the following components:

Screen (Stencil): This is the template used to carry the anti-slip pattern, typically made from finely woven mesh and processed with photosensitive or light-sensitive materials to create the design.

Squeegee System: This component evenly spreads ink across the screen, ensuring the ink passes through the mesh openings to transfer onto the sock surface.

Conveyor System: This system moves the socks, allowing the printing process to be continuous, generally using a chain or belt conveyor.

Drying System: After the ink is printed, the socks need to pass through a drying device to fix the anti-slip pattern onto the fabric, usually using hot air or ultraviolet (UV) curing methods.

Printing Process

The printing process for anti-slip socks typically includes the following steps:

Preparation: Create the screen and install it on the printing machine, while preparing the appropriate ink.

Positioning: Place the socks on the conveyor system of the printing machine, and use clamps or a vacuum system to fix the socks in place.

Printing: Start the printing machine, where the squeegee evenly transfers the ink through the screen onto the designated areas of the socks, forming the anti-slip pattern.

Drying and Curing: The printed socks pass through the drying device, where the ink is cured and firmly attached to the sock surface.

Quality Inspection and Packaging: Finally, inspect the printed anti-slip socks to ensure the pattern is complete and the anti-slip effect is adequate, then proceed with packaging.

Application Scenarios of the Anti-Slip Sock Screen Printing Machine

The anti-slip sock screen printing machine is widely used in the production of various types of socks, including but not limited to the following categories:

Children’s Anti-Slip Socks:

Children are active and energetic, and anti-slip socks effectively prevent them from slipping on smooth surfaces. Manufacturers can use screen printing machines to print various cartoon patterns on the sock soles, increasing the product’s appeal.

Elderly Anti-Slip Socks:

For the elderly who have limited mobility, using anti-slip socks can reduce the risk of falls at home or in hospital environments. Printing machines can produce simple anti-slip dots or more complex patterns based on different needs.

Sports Anti-Slip Socks:

Sports anti-slip socks are suitable for activities like yoga and dance. Screen printing machines can print high-friction anti-slip patterns to improve the stability of athletes.

Development Trends of the Anti-Slip Sock Screen Printing Machine

1. Increased Automation

With the advancement of industrial automation, modern anti-slip sock screen printing machines are gradually moving towards full automation, capable of automatically completing the entire process from sock feeding, positioning, printing, drying, to discharging. This greatly improves production efficiency and reduces human errors.

2. Multi-Color Printing Technology

Traditional anti-slip sock printing is often monochromatic; however, with the diversification of market demand, multi-color printing has become a trend. New screen printing machines can complete multi-color anti-slip pattern printing in one go, meeting consumers’ demands for personalized products.

3. Use of Environmentally Friendly Materials

As environmental awareness increases, the printing industry is gradually shifting towards eco-friendly practices. Anti-slip sock screen printing machines are increasingly using water-based inks and environmentally friendly materials, reducing environmental pollution and enhancing product safety, particularly in infant products.