What is an Ultrasonic Cutting Craftsmanship?

Ultrasonic cutting machines possess numerous unique features and advantages in the lingerie manufacturing industry, catering to a variety of applications. Here are the main characteristics, scope of application, and benefits:

Key Features:

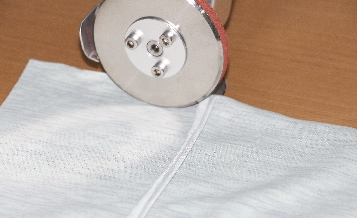

High-Precision Cutting: Ultrasonic edge cutting machines achieve precise cutting, ensuring smooth edges without burrs, enhancing overall product quality and appearance.

Non-contact Processing: Using ultrasonic edge cutting technology, tools do not directly contact the material surface, avoiding wear and contamination caused by contact and extending tool life.

High Efficiency and Speed: Ultrasonic edge cutting machines enable fast and continuous cutting, improving production efficiency, suitable for large-scale manufacturing.

Versatility: They can be applied to cutting various materials including fabrics, synthetic fibers, and films, with wide-ranging applicability.

Ease of Operation: User-friendly interface and simple operation require minimal training to operate effectively.

Energy Efficiency and Environmental Friendliness: Ultrasonic edge cutting machines operate without chemical emissions or odors, promoting energy efficiency and environmental compliance in modern manufacturing.

Scope of Application:

Lingerie Manufacturing: Used for edge cutting and trimming of various types of lingerie products such as bras, briefs, and underwear.

Apparel Manufacturing: Suitable for cutting and finishing shirts, pants, jackets, and other clothing items.

Home Textile Manufacturing: Applicable in edge cutting for bedding, curtains, and other home textile products.

Industrial Products: Used for cutting and edge finishing in automotive interiors, industrial products, and more.

Benefits:

Enhanced Product Quality: Smooth and burr-free edges improve product aesthetics and comfort, enhancing competitiveness.

Reduced Production Costs: High-efficiency and precision cutting reduce labor costs and material waste, increasing production efficiency.

Environmental and Health Benefits: Free from chemical agents or additives, no chemical pollution, meeting environmental standards and promoting employee health.

Flexibility and Adaptability: Adaptable to various materials and different cutting requirements, flexibly meeting market demands.

Time Savings: Rapid cutting speeds and continuous operation shorten production cycles, improving order execution efficiency.