The relationship between seamless underwear and hot melt adhesive film

1.What is Seamless Underwear?

Seamless underwear is a delicately designed type of lingerie with no visible seams, aimed at providing a comfortable, traceless feel. This type of underwear typically employs special seamless manufacturing techniques to reduce prominent lines or marks while wearing. The design is intended to prevent visible lines under clothing, making outerwear appear smoother and more natural.

2.What is the classification of hotmelt used in the lamination process for non-marking lingerie?

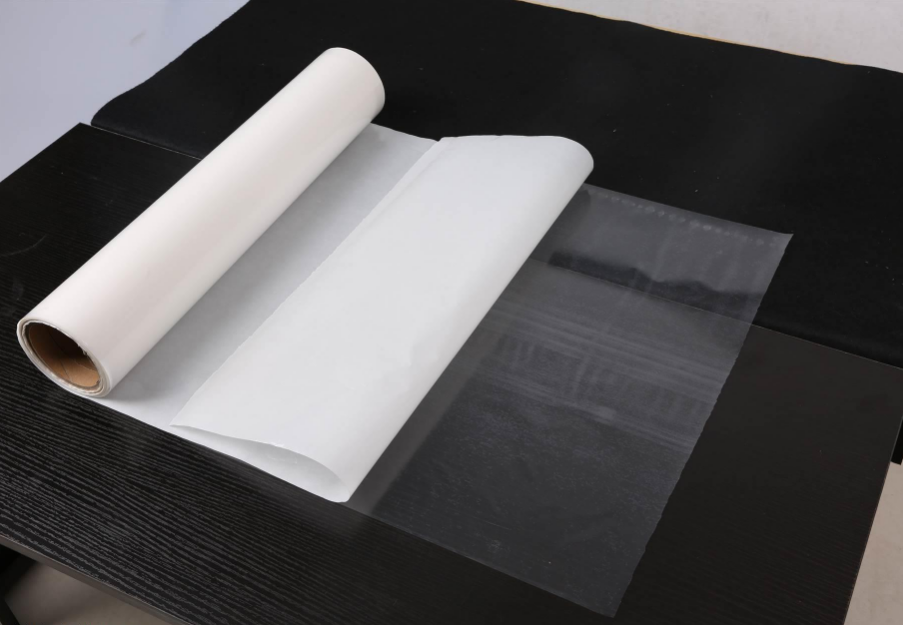

Hot Melt Adhesive Film (Thermal Bonding Film): This type of hot melt adhesive film is typically applied to lingerie fabrics through heat pressing or hot melting to achieve a seamless effect. This adhesive film possesses good bonding properties, ensuring that the lingerie has no visible lines or traces when worn.

Silicone Hot Melt Adhesive Film: This type of hot melt adhesive film contains silicone components, offering higher flexibility and comfort. Silicone hot melt adhesive film is suitable for bonding to lingerie fabrics, providing excellent adhesion while maintaining the softness of the lingerie.

Hot Melt Double-Sided Adhesive Film: This film is used in lingerie manufacturing to bond different parts of fabrics together, often applied in specific areas to ensure the structure and appearance of the lingerie. This double-sided adhesive film quickly bonds under heat pressing, providing strong fixation.

3、How to choose the type of hot melt adhesive film when producing seamless underwear?

When producing seamless underwear, selecting the appropriate type of hot melt adhesive film is crucial because different types have distinct characteristics and applications. Below are the factors to consider when selecting the type of hot melt adhesive film:

Fabric Type: Begin by considering the type of fabric used for the underwear. Different fabrics may require different types of hot melt adhesive films to ensure good bonding and comfort. For example, soft, thin, and breathable fabrics may benefit from a softer silicone hot melt adhesive film.

Bonding Effect: Choose the hot melt adhesive film based on the desired bonding effect. For a seamless and smooth finish, opt for a thermal bonding film or a hot melt adhesive film with excellent bonding properties.

Comfort: Consider the comfort and softness of the underwear. Silicone hot melt adhesive films typically offer higher flexibility and are suitable for maintaining the softness of the lingerie.

Bonding Strength: Select a hot melt adhesive film with the appropriate bonding strength based on the structure and requirements of the underwear. Double-sided adhesive films are often used in areas requiring stronger fixation.

Production Process: Take into account the requirements of the production process when choosing the type of hot melt adhesive film. Different types of adhesive films may have varying temperature, pressure, and bonding time requirements.

4、What are the advantages of MASBOND hot melt adhesive films?

Seamless Effect: MASBOND hot melt adhesive film achieves a seamless bonding effect, ensuring a smooth and seamless appearance in seamless fabric manufacturing.

High Adhesion Performance: This type of hot melt adhesive film exhibits excellent bonding performance, securely bonding fabrics while maintaining good adherence and ensuring fabric softness and comfort.

Certification: MASBOND hot melt adhesive film is certified for safety and reliability. Certification ensures that the product meets industry standards and quality requirements, providing users with a more reliable choice.

Efficient Production: Using MASBOND hot melt adhesive film improves production efficiency by enabling rapid curing, reducing production cycles, and saving costs.

Environmentally Friendly: MASBOND hot melt adhesive film is typically solvent-free, environmentally friendly, and aligns with sustainability requirements.