High efficient and Precise Laser Opening And Sewing Solution

MASBOND Full Automatic Garment Laser Pocket Welting Machine: Intelligent Upgrade Leading a New Future in Apparel Manufacturing

In the apparel manufacturing field, traditional manual pocket opening processes are not only time-consuming and labor-intensive but also require highly skilled workers—factors that greatly restrict both production efficiency and product quality. With rapid technological advancements, the MASBOND Full Automatic Pocket Opening Machine is emerging as a pivotal force in the intelligent transformation of the apparel manufacturing industry through its innovative technology and outstanding performance.

I. Product Overview

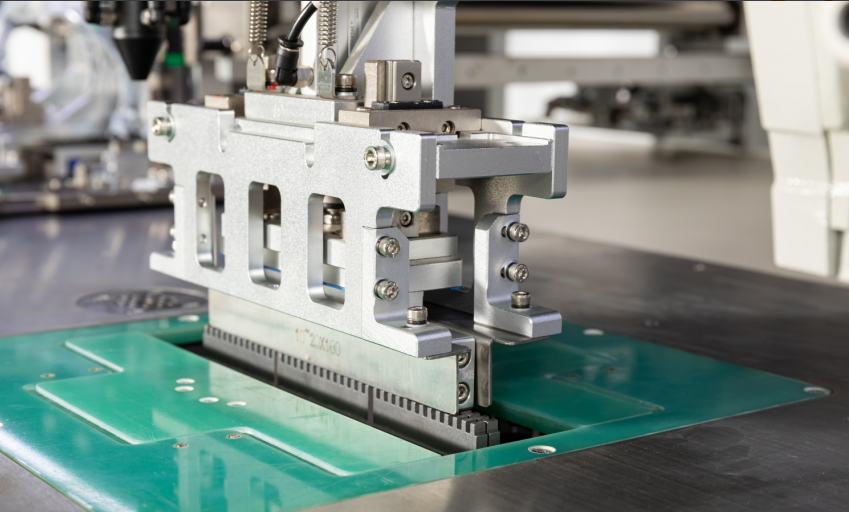

The MASBOND Full Automatic Garment Laser Pocket Welting Machine features an integrated design with a compact and stable structure. By combining laser opening, sewing, and automatic bar-tack functions into one system, it not only overcomes the limitations of traditional inner-folding techniques that restrict pocket width but also innovatively employs an outer-folding technique to achieve a minimum pocket width of 6 millimeters. This breakthrough design perfectly meets the market’s high standards for narrow pockets. Whether it is for single-flap pockets, double-flap pockets, zipper pockets, or placket openings, the machine can complete complex processes with just one button press, significantly saving labor costs and production time.

II. Core Advantages

| Comparison Items | Traditional semi-automatic devices | MASBOND Fully automatic bag opening machine | Improvement ratio |

Daily Output | 1200 | 1800 | 50% |

Operator Required | 2 people/unit | 1 person supervises 2 units | 70% manpower saving |

| Power consumption | 28.8Kw/Day | 18Kw/Day | Save 37.5% of electricity |

1. Efficient Production and Precise Control

Automated Operation: The machine is equipped with an integrated laser cutting system and adaptive sewing technology, achieving a laser precision opening of 0.01mm and a sewing accuracy of ±0.1mm. A single machine can produce over 1,800 standard pockets per day, with 850–1,200 pockets opened in 10 hours, greatly enhancing production efficiency.

Continuous and Stable Production: It supports 24-hour uninterrupted operation with a defective rate below 0.3%, ensuring high-standard stability in every process.

2. Cost Reduction, Efficiency Increase, and Energy Conservation

Labor Cost Savings: While traditional processes require 3–5 workers, MASBOND needs only one operator to supervise two machines, achieving a 70% reduction in labor costs.

Energy Savings: The optimized power consumption decreases from 28.8 kW/day to 18 kW/day, saving up to 37.5% in electricity, which offers significant cost advantages in operations.

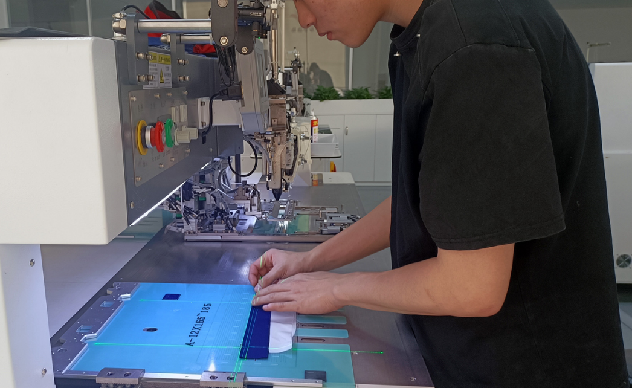

3. Versatility and Ease of Operation

Wide Fabric Adaptability: Whether dealing with knitted or woven fabrics—such as trench coats, suits, down jackets, cotton coats, heavy velvet, etc.—the machine easily handles all, meeting the production demands of various apparel products.

Intelligent Operating System: It is equipped with a spacious material loading area, precise infrared positioning, and a mid-pressure presser foot device that effectively prevents needle breaks, thread breaks, and stitch skipping. The built-in microcomputer “Spark” system supports customizable pocket patterns, coordinated by five fully servo-controlled motors, ensuring high precision and personalized design.

III. Technical Highlights and Detailed Specifications

The MASBOND Full Automatic Pocket Opening Machine not only brings revolutionary improvements in process but also boasts advanced core technical parameters:

Model: MS-KD02

Laser Power: 120W, ensuring high-precision opening

Sewing Range: Width from 1 to 2.5 cm, length from 20 to 70 cm (customizable based on different pocket designs)

Speed Setting: 100–3000 rpm/min, meeting various production needs

Main Shaft Motor: Direct-drive servo motor, ensuring stable and efficient operation

Overall Structure Dimensions: 231 × 146 × 175 cm, which guarantees production stability while facilitating factory layout

These detailed parameters not only demonstrate the machine’s high performance and reliability but also provide apparel manufacturers with a standardized and digitalized automated production solution.

IV. Profound Impact on the Apparel Manufacturing Industry

1. Dual Enhancement of Production Efficiency and Quality

Traditional manual pocket opening is not only inefficient but also prone to issues such as skewed pocket corners and uneven stitching. By leveraging precise laser positioning and intelligent control, the MASBOND machine effectively reduces defective rates and rework, fundamentally elevating the overall quality of apparel products.

2. Intelligent Manufacturing and Enterprise Transformation

Intelligent Upgrade: With integrated functions including automatic material feeding, laser opening, precise sewing, and automatic "da zao", the machine enables full-process automated production, assisting the apparel manufacturing industry in its shift toward intelligent and digitalized operations.

Competitive Advantage: While reducing dependence on manual labor and energy consumption, the machine can quickly respond to market demands for personalized designs, thereby strengthening an enterprise's core competitiveness in a highly competitive market.

3. Sustainable Industry Development

By lowering production costs, increasing efficiency, and ensuring product quality, the MASBOND Full Automatic Pocket Opening Machine not only drives the large-scale development of individual enterprises but also injects new momentum into the sustainable development of the entire apparel manufacturing industry.

V.Conclusion

MSABOND Full Automatic Garment Pocket Opening Machine, leveraging its leading laser precision pocket opening technology, adaptive sewing system, and innovative external folding design, delivers unprecedented improvements in production efficiency and product quality to the traditional apparel manufacturing industry. It demonstrates strong competitive advantages in reducing labor costs, saving energy, and meeting personalized product demands. As an intelligent, revolutionary product in the apparel manufacturing sector, this full automatic garment pocket opening and sewing machine is equipped with a laser cutting system and adaptive sewing technology, enabling apparel companies to swiftly overcome production capacity bottlenecks. In today's era of accelerating intelligent manufacturing and digital transformation, MSABOND is poised to lead industry innovation and transformation, making significant contributions to sustainable development and market breakthroughs.

The professional seamless bonding machine supplier and other automation solution provider - MASBOND

MASBOND founded in 2019, is focused on providing the latest seamless bonding solutions and other automation solutions to our clients. We are specialized in supplying kinds of seamless tape bonding machines, silicone glue bonding machines,automatic laser pocket welting machines etc.

MASBOND boasts a team of excellent experts dedicating to designing seamless processes and devoted to providing MASBOND solutions of seamless and automation to our customers with first-class products, outstanding credibility and meritorious service.

Need Seamless Bonding Machines or other automatic machines for your Shop or Factory? Welcome to contact MASBOND, and we will reply within 24 hours.