2025 Non-Acetate Shoelaces The Future of Sustainable Footwear Manufacturing

Non-Acetate Shoelaces: The Future of Sustainable Footwear Manufacturing

A Technical Deep Dive for Eco-Conscious Brands

As global demand for environmentally responsible footwear surges, non-acetate shoelaces have emerged as a critical innovation for brands committed to reducing their ecological footprint. This cutting-edge solution redefines accessory manufacturing by merging sustainability with industrial-grade performance, offering a blueprint for ethical production without sacrificing quality.

Why Non-Acetate Shoelaces Are Disrupting the Industry?

Traditional shoelace manufacturing has long relied on acetate coatings and plastic films to seal edges—a process with hidden environmental costs. These methods generate microplastic waste, consume excess energy, and depend on petrochemical derivatives. Non-acetate technology eliminates these issues through three transformative advancements:

Zero-Toxin Ultrasonic Bonding

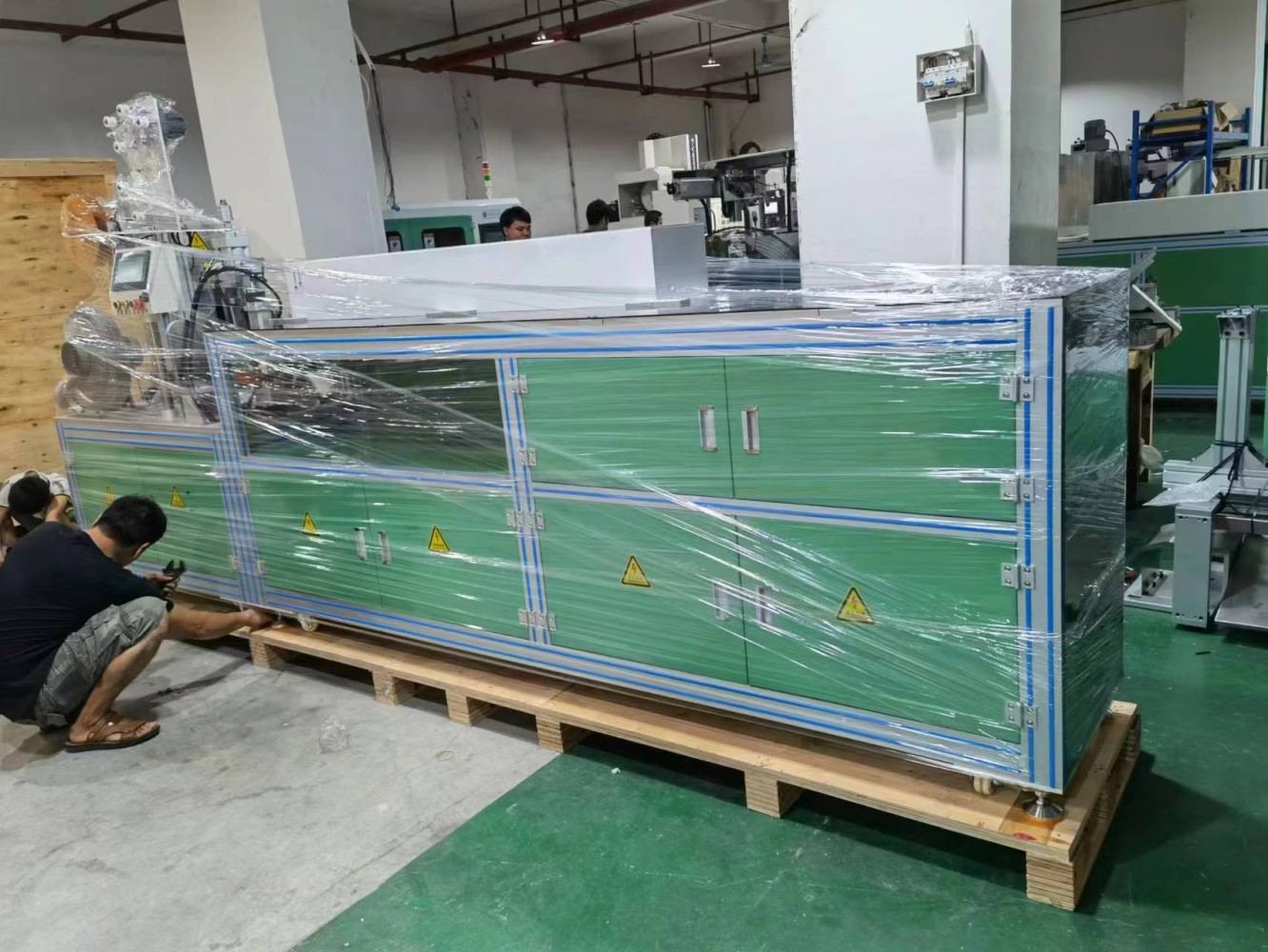

Masbond’s proprietary ultrasonic welding system replaces heat-press adhesives with high-frequency vibrations. This friction-based process melts lace fibers at the molecular level, creating permanent seals without glues, solvents, or plastic films.

Laser Precision for Waste Reduction

Integrated laser cutters achieve ±0.5mm accuracy, minimizing material waste while enabling unlimited customization. Brands can produce short runs of specialty lengths and widths without costly retooling.

Closed-Loop Production

The fully automated system recaptures 98% of textile offcuts for recycling, aligning with circular economy principles.

Environmental Impact: By the Numbers

72% lower carbon emissions compared to conventional heat-press methods

Zero wastewater from chemical rinses or dye fixation

100% REACH/ROHS compliance for EU market access

3x longer product lifespan due to fray-resistant edges

Quality Benchmarks for Brand Partnerships

Non-acetate laces resolve longstanding durability issues in eco-friendly footwear:

Performance Validation

Withstands 50+ industrial wash cycles (ISO 6330)

UV-resistant pigments prevent color bleed (AATCC 16-2020)

Tensile strength exceeding 200N (SATRA TM114)

Supply Chain Advantages

30% faster lead times via digital template systems

MOQs reduced to 500 pairs for niche collections

Pantone-matched batches with ≤0.9 ΔE color variance

Market Differentiation for Forward-Thinking Brands

Consumer studies reveal 68% of buyers prioritize eco-verified accessories when selecting footwear.

By adopting non-acetate laces,brands gain:

Marketing leverage with certifications like OEKO-TEX and GRS (Global Recycled Standard)

Cost predictability through stable pricing unaffected by acetate market volatility

Design freedom with metallic foils, recycled PET blends, and biodegradable fiber options

Implementation Roadmap

Material Audit: Transition 1-2 hero product lines to non-acetate laces

Co-Branding: Highlight shoelace innovation in sustainability reports

Lifecycle Marketing: Educate consumers on end-of-life composting and recycling

The Bottom Line

Non-acetate shoelace technology isn’t just an accessory upgrade—it’s a strategic investment in scalable sustainability. As circular design becomes non-negotiable for regulators and consumers alike, early adopters will cement their position as leaders in the $380 billion global footwear market.

Meta Description

Cut emissions and boost durability with ultrasonic-bonded non-acetate shoelaces. EU-compliant, machine-washable, and 100% plastic-free. Download technical specifications today.