Hot Air Seam Sealing Machine

MASBOND Hot Air Seam Sealing Machine MS-2272

The hot air seam sealing machine stands out as a critical component in the production of high-performance and weather-resistant textiles. This specialized piece of equipment plays a pivotal role in ensuring the integrity of seams, making it a cornerstone in the creation of waterproof and durable products.

MASBOND Hot Air Seam Sealing Machine MS-2272

Overview of MASBOND MS-2272 Hot Air Seam Sealing Machine:

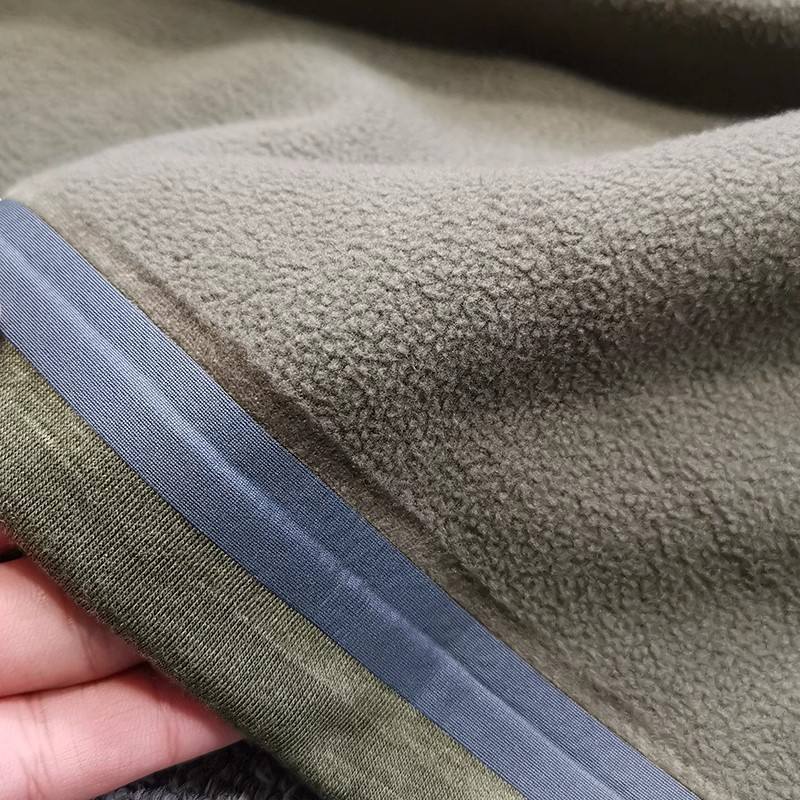

A hot air seam sealing machine is a specialized piece of equipment used in the textile and garment industry for waterproofing seams on various products such as rainwear, tents, outdoor gear, and other items that require water resistance. The process of seam sealing involves applying heat and pressure to a seam tape or adhesive, which then bonds with the fabric, creating a water-resistant barrier。

Principle of Operation:

Hot air seam sealing machines use a combination of heat and pressure to activate and melt the adhesive on seam tapes.

The machine typically includes a hot air nozzle or heating element, a pressure roller, and conveyor systems to move the material through the sealing process.

Components:

Hot Air Nozzle: Emits a controlled stream of hot air to activate the adhesive on the seam tape.

Pressure Roller: Applies pressure to ensure proper bonding between the seam tape and the fabric.

Conveyor System: Moves the material through the machine at a consistent speed to ensure uniform sealing.

Seam Tape Application:

The seam tape, often made of thermoplastic materials, is applied to the seams of the fabric.

As the material passes through the machine, the hot air nozzle heats the adhesive on the seam tape, causing it to bond with the fabric.

Temperature and Speed Control:

Hot air seam sealing machines usually have temperature and speed controls to accommodate different types of fabrics and seam tapes.

These controls help optimize the sealing process for specific materials, ensuring a secure and durable seam.

Versatility:

The machines are versatile and can be used on various fabrics, including those used in outdoor and technical garments, ensuring that the final product is waterproof and weather-resistant.

Features of MASBOND MS-2272 Hot Air Seam Sealing Machine:

Temperature Control:

Adjustable temperature settings allow operators to tailor the heat level to the specific requirements of different fabrics and seam tapes.

Speed Control:

Variable speed controls enable operators to adjust the conveyor speed, ensuring optimal sealing for different materials and production volumes.

Precise Hot Air Nozzle:

Machines are equipped with precise hot air nozzles that deliver a controlled and consistent flow of hot air to activate the adhesive on the seam tape.

Pressure Rollers:

Pressure rollers ensure uniform pressure on the seam tape, facilitating strong and consistent bonding with the fabric.

Multiple Nozzle Configurations:

Some machines come with multiple nozzle configurations to accommodate different seam widths and shapes.

Conveyor System:

Conveyor systems are designed for smooth material transport through the machine, promoting even seam sealing and preventing material distortion.

Touchscreen Interface:

Advanced models may feature a touchscreen interface for easy and intuitive control of temperature, speed, and other settings.

Safety Features:

Built-in safety features, such as emergency stop buttons and safety interlocks, ensure operator safety during the operation of the machine.

Built-in Cooling System:

Some machines come with a built-in cooling system to rapidly cool the sealed seams, reducing the time required for the finished product to be ready for further processing.

Programmable Settings:

Programmable settings allow operators to save and recall specific configurations, streamlining the setup process for different materials and production runs.

Integrated Exhaust System:

An exhaust system helps remove fumes and prevents the accumulation of heat within the machine, contributing to a safer working environment.

Durability and Build Quality:

Robust construction and durable materials ensure the longevity of the machine, even in high-volume production environments.

Maintenance Features:

Easy access to key components and maintenance features simplify routine maintenance tasks, contributing to the overall reliability of the machine.

Compact Design:

Compact and space-efficient designs are advantageous for manufacturers with limited floor space in their production facilities.

Energy Efficiency:

Energy-efficient features, such as rapid heating elements and standby modes, contribute to lower operational costs and environmental sustainability.

Applications of MASBOND MS-2272 Hot Air Seam Sealing Machine:

Hot Air Seam Sealing Machines find widespread applications in various industries, especially in the textile and garment manufacturing sector. The primary purpose of these machines is to enhance the water resistance of products by sealing seams effectively. Here are some key applications of hot air seam sealing machines:

Outdoor Apparel:

Hot air seam sealing machines are extensively used in the production of outdoor apparel such as rain jackets, windbreakers, snowsuits, and other outerwear. Sealed seams ensure that these garments remain waterproof and weather-resistant.

Sportswear:

Sportswear, including items like sports jackets, pants, and athletic gear, often requires seam sealing to provide protection against rain and other environmental conditions. Hot air seam sealing ensures that these garments maintain their performance features.

Military and Tactical Gear:

Military and tactical gear, such as combat uniforms, rainwear, and other specialized clothing, benefit from seam sealing to enhance durability and weather resistance in various operational environments.

Workwear:

Certain types of workwear, particularly those worn in outdoor or harsh conditions, may undergo seam sealing to improve water resistance and overall durability.

Footwear:

Some types of footwear, especially outdoor and performance footwear like hiking boots and snow boots, may have seams that require sealing to prevent water infiltration.

Tents and Outdoor Gear:

Hot air seam sealing is crucial in the manufacturing of outdoor gear, including tents, backpacks, and other camping equipment. This ensures that these items can withstand the elements and keep the contents dry.

Medical and Protective Clothing:

Certain medical garments and protective clothing used in cleanroom environments, laboratories, or hazardous conditions may undergo seam sealing to enhance their integrity and resistance to liquids.

Automotive Upholstery:

Hot air seam sealing machines are employed in the automotive industry for sealing seams in vehicle upholstery and interiors. This helps improve the water resistance of car seats and other components.

Awnings and Tarps:

Products such as awnings and tarps used for outdoor applications benefit from seam sealing to ensure water resistance and protection against the elements.

Bags and Luggage:

Sealing seams in bags, backpacks, and luggage items ensures that these products remain water-resistant and durable, particularly when used in travel or outdoor activities.

Inflatable Products:

Some inflatable products, such as inflatable boats or water sports equipment, may undergo seam sealing to prevent leaks and ensure their integrity.

Medical Textiles:

Certain medical textiles, such as patient gowns or surgical apparel, may utilize seam sealing to enhance barrier properties and prevent fluid penetration.

In essence, hot air seam sealing machines play a critical role in industries where water resistance and durability are essential characteristics of the final products. The applications span a wide range of consumer and industrial goods that require protection against moisture and the elements.

MASBOND MS-2272 Hot Air Seam Sealing Machine supplier:

MASBOND is the new brand under Hunan Mascoon Machinery Technology Co.,ltd, which is not only a professional manufacturer but also a good trader for all automatic textile machines. With reasonable prices, fast response, and professional service, we have won a large group of customers from home and abroad. If you are looking for a solution for automatic textile machines, welcome to consult us.

If you are looking for high quality MASBOND MS-2272 Hot Air Seam Sealing Machine in bulk, feel free to contact us to get the latest price.

Technical Parameters of MASBOND MS-2272 Hot Air Seam Sealing Machine :

Model | MS-2272 | Voltage | AC220v |

Frequency | 50/60hz | Welding Area | 14-23MM |

Welding speed | 1-22M/Min | HS Code | 8451300000 |

Get A Quote

Feel free to have a quote on our tapes, we will reply within 48 hours.